Electronic balance weighing software is a management software developed by bernita software department for the company's series of balances and weighing equipment. Designed to improve productivity and accuracy, avoid errors and support relevant regulatory requirements. It can save the time originally spent on manual recording and transcribing to reports or application software. At the same time, you can easily save the weighing results: automatically send the data to the database, the Internet or any other destination. For users to query and analyze historical data. And by connecting all your scales through the company network, you can centrally control user management, weighing applications and calibration procedures. Suitable for most users.

At the same time, it provides secondary customized development of software according to customer needs.

Main features and functions of the software:

1. Support most scales and weighing scales equipped with RS 232 / 485 / Modbus / TCP protocol and interface, such as sedolis, sitmatou and Mettler. Toledo et al

2. Simple setting and convenient operation

3. Add time & date to your data and make statistical query according to the date

4. Configurable data format, easy to export to excel, TXT text, etc

5. Transfer data to Windows based programs, such as Excel and word, to facilitate printing.

6. User defined information can be automatically added to the data

7. Set the automatic data transmission function to prevent the operator from manual errors or human factors and automatically count the measurement times.

Types and brands of scales and scales suitable for the software:

1. Ultramicro electronic balance: such as Mettler's umt2 electronic balance, etc

2. Microbalances: such as Mettler's at21 electronic balance and sartoruis's S4 electronic balance.

3. Semi microbalances: such as Mettler's ae50 electronic balance and sartoruis's m25d electronic balance

4. Constant electronic balance: such as Mettler's ae200 electronic balance and sartoruis's a120s and a200s electronic balance

5. Analytical balance: the general name of constant balance, semi microbalance, microbalance and ultra microbalance.

6. Precision electronic balance: electronic balance with accuracy class II.

System composition and Application

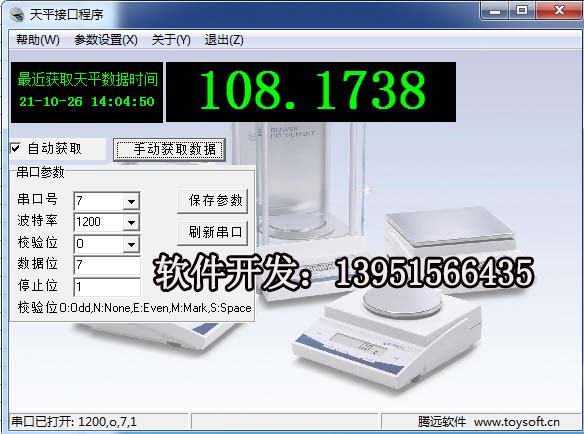

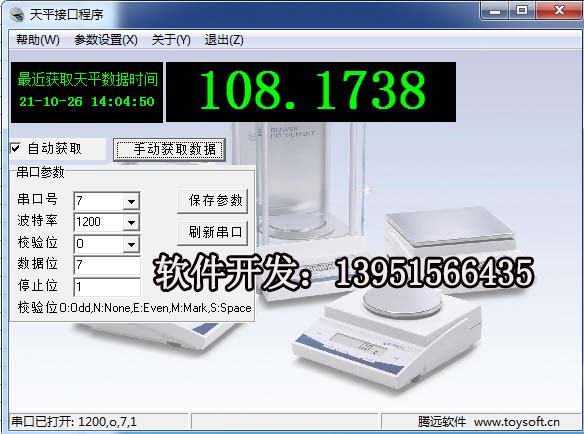

Structure: experimental balance, communication cable, data interface module, data acquisition program, computer, database, balance management software.

Application scenario: the electronic balance data acquisition system is used to automatically collect the physical property test data of soil such as water content, liquid plastic limit, density and specific gravity, overcome human errors and improve the test efficiency. The balance software guides you through the SOP workflow on all connected scales to ensure that each operator follows the same procedure. Allows you to easily customize each method as required. Reduce errors and calculation errors - let the software automatically perform all calculations and immediately feed back to you the results within the defined tolerance range. Avoid manual input errors and ensure weighing accuracy.

The balance software is fully integrated with laboratory information systems (e.g. LIMS) and chromatographic software to ensure seamless data flow throughout the analytical workflow. Send the weighing results directly to the operation requiring the weight value for subsequent analysis, and ensure that it can be traced back to the starting point. Automatically complete cumbersome weighing work (such as sample and standard solution preparation), improve processing capacity and reduce the cost of each sample.

All metadata is automatically stored in a central database when it is created. Installing Tengyuan balance weighing software in the laboratory can reduce the time required for manual data recording and eliminate the risk of transcription errors.

By using Tengyuan electronic balance software, you are ready for audit at any time: you can access data 24 / 7 from any location and generate reports tailored to your needs. The software can help you meet the security requirements related to data reliability.

Meet regulatory requirements: use centralized user management, cooperate with electronic signature and audit tracking to easily and efficiently meet compliance and data reliability requirements.

A software platform is used for various instruments: through seamless integration with other systems, process control is realized, system maintenance is simplified, and the workload of training and verification is reduced.

Software operation demonstration video:

https://v.qq.com/txp/iframe/player.html?vid=c3307s14at7

Live video shooting

https://v.qq.com/txp/iframe/player.html?vid=i33070u7ht2